Ngami Project

A large scale In Situ Copper Recovery development opportunity

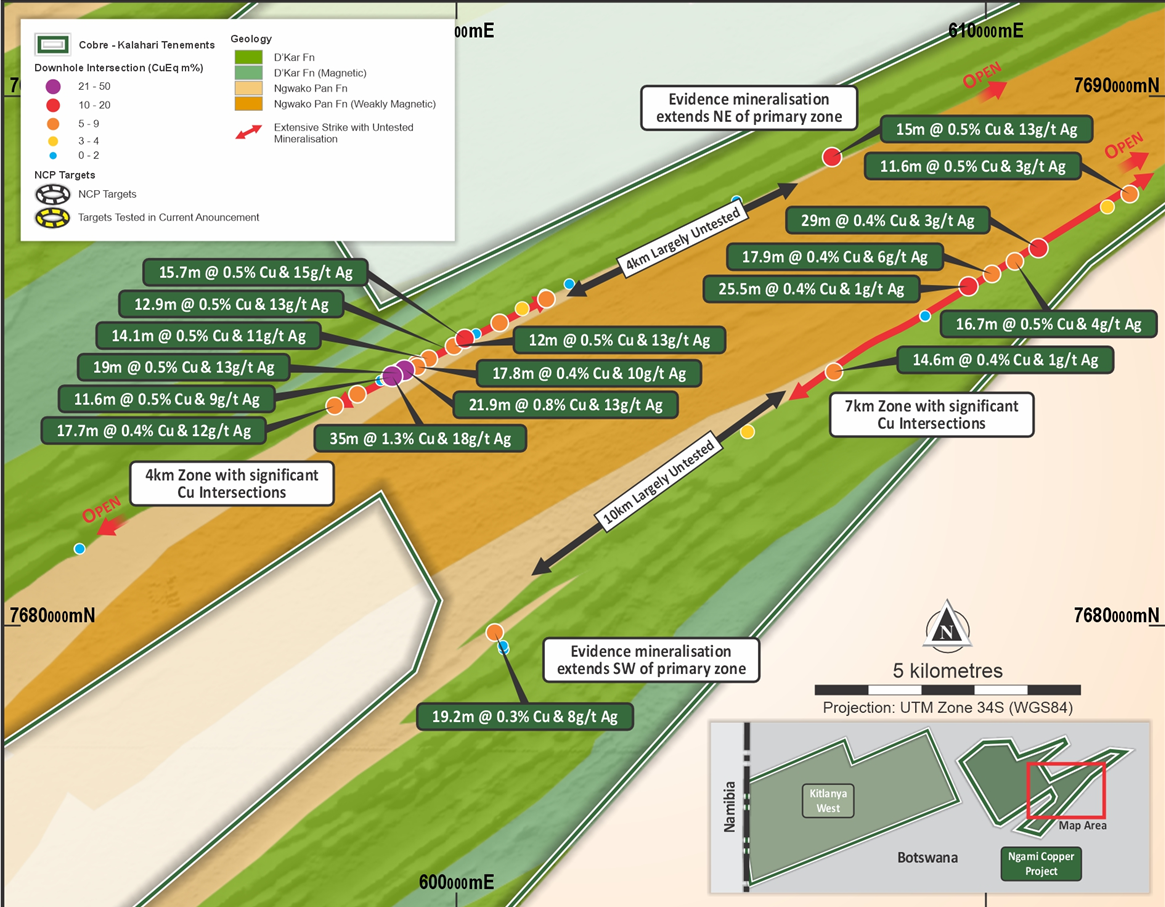

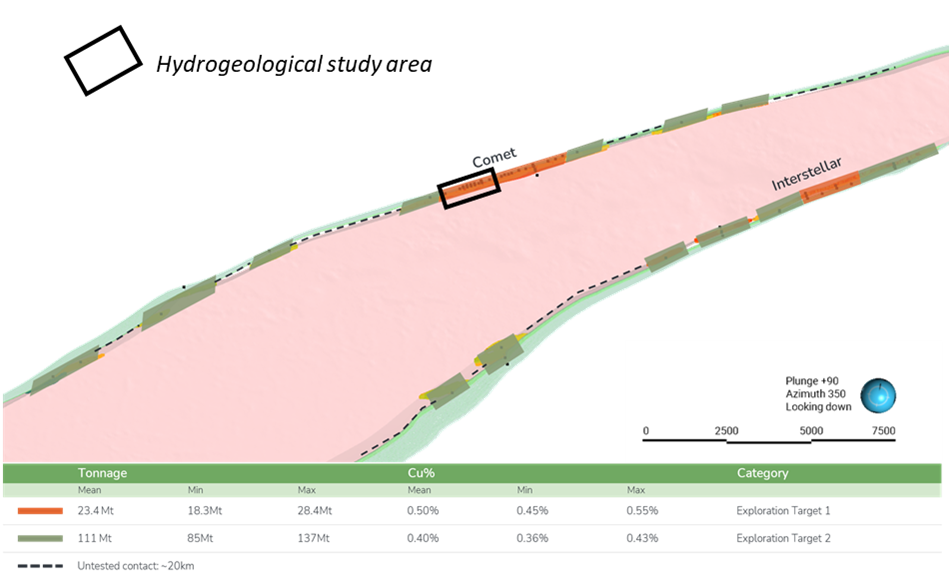

Covering a project area of 727 km2, Cobre’s flagship Ngami Copper Project (NCP) is a copper and silver development opportunity with estimated scale of between 103Mt and 166Mt @ 0.38 to 0.46% Cu1

Key Facts

- 40km strike of copper silver mineralisation

- Consistent chalcocite mineralisation intersected along extensive strike lengths

- Structurally controlled high-grade intersections include:

- 9.3m @ 3.4% Cu and 30g/t Ag

- 10.7m @ 1.3% Cu and 18 g/t Ag

- Potential for large moderate grade deposit with smaller high-grade deposits

- Mineralisation satisfies key criteria for in-situ copper recovery providing a potential low CAPEX development pathway

1 Refer ASX announcement dated 4 June 2024. At this stage the results are in an exploration target category. The estimates of tonnage and grade are conceptual in nature, there has been insufficient exploration to estimate a Mineral Resource and it is uncertain if further exploration will result in the estimation of a Mineral Resource.

In-Situ Copper Recovery (ISCR) Process

Background to ISCR

In-situ extraction has been used effectively for over 50 years. For copper recovery, the method utilises a series of injection wells to pump a weak acid (similar pH to lemon juice) solution under low pressure to dissolve the copper (and silver) mineralisation in situ. The method relies on naturally developed fractures to focus the solution into the orebody where the copper is leached after which the copper-rich solution is pumped to surface through recovery wells for processing into copper cathode sheets using an electro-chemical process that separates the copper from the solution. As there is no need for excavation, mine development, waste piles, milling or smelting, the technique provides a cost-effective technology with an extremely small environmental footprint.

For a deposit at NCP to be considered viable for ISCR, several specific hydrogeological and metallurgical factors need to be satisfied:

1. Is the mineralisation amenable to acid leaching?

Mineralisation is predominantly fine-grained chalcocite easily treated with an acid leach process.

Mineralisation is hosted in fractures and along cleavages, providing porosity and permeability and providing fluid flow through the mineralised horizon for the leaching solution.

IBR Leach tests carried out on approximate 5m composite samples of moderate- and high-grade intersections have confirmed an acid leach with ferric sulphate and chloride is viable for copper and silver extraction.

2. Is the mineralisation below the water table?

Groundwater measurements estimate the water table to be at 123m depth below surface.

This appears to be an optimal depth, sufficiently below the Kalahari cover to ensure fracture control preventing lateral migration, with a small portion of the orebody exposed above the water table.

3. Does the host rock have fractured permeability for solution to permeate through and dissolve the copper?

Detailed fracture logging and AI driven fracture logging carried out on holes through the Comet Target has confirmed:

High density fracture zone associated with the lower mineralised cycle of the D’Kar Formation, particularly associated with the mineralisation above the footwall contact.

Lower (less-permeable) fracture counts associated with the underlying Ngwako Pan Formation footwall and overlying sandstone packages in the D’Kar Formation provide lateral seals.

The primary fracture orientation is sub-parallel to the (mineralised) D’Kar/Ngwako Pan Formations redox contact, allowing fluid flow parallel to and along the contact zone.

Cobre has completed a series of injection tests demonstrating that the permeability of mineralised fracture zone is suitable for ISCR.

Long-section through a portion of the Comet Target illustrating a conceptual in-situ copper recovery process. Injection and recovery wells would be reversed as the operation progresses along strike. Ground water pH is restored behind the operation ensuring minimal environmental footprint.

Ngami Copper project Timeline

2024:

- Commencement of advanced metallurgical test work to simulate in-situ conditions and recoveries

- Hydrogeological tests confirm viability ISCR

- Commencement of Scoping Study to provide design and financial estimate of an ISCR process.

- Completion of initial hydrogeological testwork demonstrating that the primary fracture zone has the necessary porosity for injection

2023:

- 5,300m of diamond drilling tests multiple copper-silver targets in the area surrounding Comet proving continuity of mineralisation over 10s of kms

- Airborne gravity gradient survey highlights potential sub-basin with a potential intrabasin high associated with the main mineralised zones

- Ground gravity orientation survey over Comet as well as Ionic leach survey provide potential vectors for identifying high-grade portions of targets.

2022:

- 7,750m of diamond drilling completed with the focus on delineating copper-silver mineralisation in the 4km strike length Comet Target.

2019:

- Early drill testing of AEM conductors and the northern anticline contact provides important stratigraphic information

- Regional and detailed AEM surveys completed.

- High resolution magnetic survey completed.

Historical:

- 11,400 soil samples, and 11,693 kms of high-resolution magnetics and 2,046m of diamond drilling collected in 2014.

Geology and Mineralisation

The copper-silver mineralisation at NCP is sedimentary-hosted, structurally controlled, and associated with the redox contact between oxidised Ngwako Pan Formation red beds and overlying reduced marine sedimentary rocks of the D’Kar Formation on the limbs of anticlinal structures. Drilling has focussed on the southern anticlinal structure which extends for over 40km across the NCP with evidence for anomalous copper-silver mineralisation on both northern and southern limbs.

Drilling results to date have returned consistent, wide intersections of anomalous to moderate-grade copper-silver values over extensive strike lengths with smaller structurally controlled higher-grade zones. This style of mineralisation is dominated by fine-grained chalcocite which occurs along cleavage planes (S1) and in fractures rather than the vein hosted bornite with chalcopyrite more typical of the KCB style. Importantly, the chalcocite mineralisation is amenable to acid leaching, occurs below the water table and is associated with well-developed fracture zones bounded by more competent hanging and footwall units satisfying key considerations for ISCR.